Summary

This article provides a comprehensive guide to vehicle exhaust hose reels, covering their benefits, types, functionality, and selection criteria. It explains how hose reels enhance workplace safety, optimize space, improve equipment longevity, and create more efficient operations in automotive service facilities. The guide details four main types of hose reels (light duty, spring operated, motorized, and specialty/oversized), explains their components and operation processes, and offers guidance on selecting the right system based on vehicle types, facility layout, usage patterns, and budget considerations.

In automotive service centers, repair shops, and maintenance facilities, proper air quality management isn't just about compliance—it's essential for worker health, safety, and productivity. Vehicle exhaust removal systems are a critical component of this equation, and hose reels represent one of the most versatile and efficient solutions available.

Hose reels for vehicle exhaust extraction provide a compelling combination of functionality, convenience, and workplace organization. By keeping potentially hazardous exhaust hoses neatly stored when not in use and readily accessible when needed, these systems help maintain both a safer working environment and a more efficient operation.

This comprehensive guide will explore everything you need to know about vehicle exhaust hose reels—from understanding the various types available to selecting the right solution for your specific needs and budget. Whether you're upgrading an existing system or installing equipment in a new facility, this information will help you make informed decisions that protect your workforce and optimize your workspace.

Why Choose Hose Reels for Vehicle Exhaust Removal?

Enhanced Workplace Safety

According to NIOSH, long-term exposure to carbon monoxide from vehicle exhaust, especially in enclosed service bays, can lead to serious health concerns, making proper extraction systems essential. Workplace safety also begins with proper organization. Loose exhaust hoses on shop floors create tripping hazards that can lead to injuries and workflow disruptions. Hose reels eliminate this risk by keeping hoses suspended and out of the way when not in use.

Space Optimization

Floor space in repair shops and service centers is valuable real estate. Overhead hose reels free up this space by storing hoses above the work area. This vertical storage solution maximizes available floor area for equipment, vehicles, and personnel movement.

Improved Hose Longevity

Exhaust hoses that are left on the floor are subject to being run over, stepped on, and damaged. By keeping hoses elevated and properly stored on reels, you significantly extend their useful life, reducing replacement costs and maintenance downtime.

Efficient Operation

When technicians need to connect to a vehicle's exhaust system, having a hose reel system means they can quickly pull down the necessary length of hose, make the connection, and get to work. This efficiency translates to faster service times and improved productivity.

Professional Appearance

A well-organized shop with neatly stored equipment projects professionalism to customers and inspectors alike. Hose reels contribute to a clean, organized appearance that instills confidence in your operation.

Types of Hose Reels

Light Duty Hose Reels

Light Duty Hose ReelsLight duty hose reels provide an affordable solution without sacrificing essential functionality. While they may not offer all the features of higher-end models, these reels effectively manage exhaust extraction needs in environments where heavy-duty performance isn't required.

|

Key Features:

|

Best For:

|

Spring Operated Hose Reels

Spring Operated Hose ReelsSpring hose reels represent the versatile middle ground in the hose reel spectrum. Their durable construction and reliable operation make them suitable for most standard automotive applications. The manually operated spring mechanism provides controlled retraction when the hose is released, automatically storing the hose neatly on the reel.

|

Key Features:

|

Best For:

|

Motorized Hose Reels

Motorized Hose ReelsMotorized hose reels represent the premium tier of exhaust extraction solutions. By eliminating the need for manual pulling and pushing, these systems reduce technician fatigue and enhance workplace efficiency. The powered retraction ensures consistent hose management regardless of length or diameter, while remote control capabilities allow for convenient operation from anywhere in the work area.

|

Key Features:

|

Best For:

|

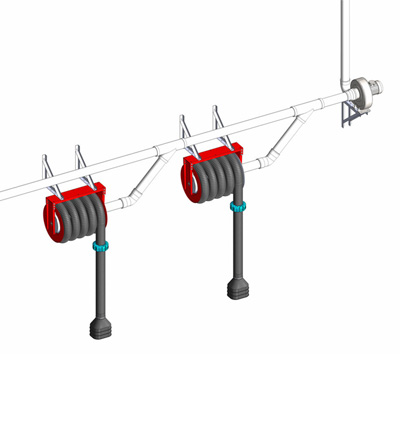

Specialty & Oversized Hose Reels

Specialty & Oversized Hose ReelsWhen standard solutions don't meet specific needs, specialty and oversized hose reels fill the gap. These custom-configured systems are designed to handle the most demanding applications, from military transport vehicles to mining equipment. Their robust construction and specialized features ensure reliable operation even in extreme conditions.

|

Key Features:

|

Best For:

|

How Exhaust Hose Reels Work

Understanding the mechanics behind hose reel systems helps in making informed decisions about installation and usage. Here's a breakdown of how these systems function:

Components of a Hose Reel System

- Reel Assembly: The central drum mechanism that stores the hose when not in use

- Hose: Specialized high-temperature flexible ducting designed to capture and transport exhaust gases

- Tailpipe Adapter: Connects the hose to the vehicle's exhaust pipe

- Mounting Hardware: Brackets and supports that secure the reel to ceiling, wall, or floor

- Retraction Mechanism: Spring assembly or electric motor that winds the hose back onto the reel

- Locking Mechanism: Allows the hose to be locked at desired lengths during use

- Ductwork Connection: Connects the hose reel to the building's exhaust ventilation system

- Control Systems: For motorized units, the switches, remotes, or automation that controls operation

Operation Process

Spring-Operated Systems:

- Technician pulls the hose down from the reel to the required length

- Internal ratchet mechanism locks the hose in place

- Adapter is attached to the vehicle's exhaust pipe

- After use, a slight tug releases the locking mechanism

- Spring tension automatically retracts the hose back onto the reel

Motorized Systems:

- Technician activates the motor via wall switch or remote control

- Motor unwinds the hose to the desired length

- Adapter is attached to the vehicle's exhaust pipe

- After use, motor is activated again to retract the hose

- Automatic stop mechanisms prevent over-retraction

Both systems efficiently connect to your facility's existing ductwork or directly to exhaust fans, creating a complete path for harmful emissions to be safely removed from the workspace.

Selecting the Right Hose Reel

Choosing the appropriate hose reel system involves evaluating several factors specific to your operation:

Assessment Factors

1. Vehicle Types

The vehicles serviced in your facility directly impact your hose reel requirements:

- Passenger Vehicles: Typically require 3"-4" hose diameter

- Light Commercial: Usually need 4"-5" hose diameter

- Heavy-Duty Trucks: Often require 5"-6" hose diameter

- Specialized Equipment: May need custom solutions with 6"+ diameter

2. Facility Layout

Your physical space determines mounting options and hose length requirements:

- Ceiling Height: Affects mounting method and accessible reach

- Bay Size: Determines required hose length when extended

- Structural Support: Influences mounting possibilities

- Existing Obstacles: May impact placement options

3. Usage Patterns

How the system will be used affects which type of reel is most appropriate:

- Frequency of Use: Higher usage favors more durable motorized options

- User Accessibility: Hard-to-reach installations benefit from motorized operation

- Duty Cycle: Heavy usage scenarios require robust construction

- Operational Hours: Extended operation periods justify higher-tier systems

4. Budget Considerations

Finding the balance between initial investment and long-term value:

- Initial Purchase Cost: Light duty systems offer lower entry costs

- Installation Expenses: Consider contractor fees and additional materials

- Operational Costs: Motorized systems have minimal additional energy requirements

- Maintenance Requirements: Higher-quality systems typically offer lower lifetime costs

- Expected Lifespan: More robust systems generally provide longer service life

Hose Reel Benefits

Direct Benefits

Reduced Energy Costs: By extracting only at the source, you minimize the tempered air being exhausted from your facilityLower Maintenance Expenses: Properly stored hoses experience less damage and require less frequent replacement

Increased Productivity: Technicians spend less time managing hoses and more time performing billable work

Extended Equipment Life: Vehicles and tools experience less corrosion from exhaust exposure

Reduced Cleaning Costs: Less exhaust residue on floors, walls, and equipment

Indirect Benefits

Improved Worker Health: Fewer sick days and potential long-term health issuesEnhanced Workplace Safety: Reduced tripping hazards and accidents

Better Compliance: Meets or exceeds OSHA's indoor air quality guidelines

Improved Reputation: Demonstrates commitment to employee welfare and environmental responsibility

Higher Employee Satisfaction: Creates a cleaner, more professional work environment

Vehicle exhaust hose reels represent a significant advancement in automotive workplace safety and organization. By keeping dangerous emissions controlled and hoses neatly stored, these systems create a safer, more efficient, and more professional work environment.

Whether you select a light-duty system for occasional use, a robust spring-operated solution for daily operation, or a premium motorized system for maximum convenience, the investment delivers tangible returns through improved air quality, enhanced productivity, and reduced maintenance costs.

Fume-A-Vent offers comprehensive solutions for facilities of all sizes, with expert consultation available to help you select the perfect system for your specific needs. From initial assessment through installation and ongoing support, our team ensures you receive the ideal exhaust removal solution for your facility.

You may also like: