Articulating boom arm simple drop systems are built for shops with overhead cranes or high ceilings where traditional overhead systems won't work. These pivoting boom arms mount flush against the wall when not in use, then swing out over or between bays as needed, maximizing floor space and crane clearance.

With a scissoring midpoint joint, articulating boom arms deliver exceptional flexibility and extended reach, making them ideal for diesel engine repair shops handling everything from tractors to heavy mining equipment.

Hose Temps: 400° / 600°

Hose Diameters: 4 to 10 inches

Length: 10, 15, and 20 feet

Tractor Exhaust Removal

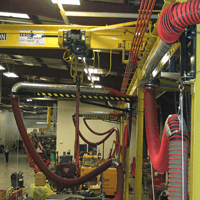

Fume-A-Vent Boom Arms for Diesel Power Equipment Co.

Application

Articulating boom arm systems installed at Diesel Power Equipment Co., a full-service diesel engine repair facility

Summary

Diesel Power Equipment Co. operates a comprehensive diesel repair facility specializing in overhaul, welding, and fabrication services for heavy equipment. The shop provides engine performance testing and diagnostics, hydraulic testing, fluid analysis, and complete rebuilds of cylinders, pumps, hydrostat/power-shift transmissions, and steering systems. Their service capabilities extend to engines, generators, tractors, construction equipment, and mining machinery.

Challenge

The shop required an exhaust removal solution that could accommodate their overhead jib crane while delivering 25 feet of reach across their expansive work area. The system needed to effectively capture diesel exhaust, welding fumes, dust, and hazardous airborne contaminants without disrupting crane operations or impeding technician movement and workflow.

Solution

Fume-A-Vent installed articulating boom arms with cable balancers for smooth hose positioning and compact storage. The wall-mounted boom arms extend up to 25 feet when in use, providing the necessary reach for servicing large diesel equipment. Their articulating design enables technicians to position exhaust hoses exactly where needed, then fold them completely out of the crane's operating path during heavy lifting operations.

This system provides Diesel Power Equipment Co. with the flexibility to capture contaminants across multiple work zones while preserving full overhead crane access, essential for maneuvering heavy engine components and equipment safely throughout the facility.